Effleurage

A technique that is rarely used these days as it is too expensive. It reached its peak in 1860 and made the reputation of the city of Grasse. The delicate flowers are placed on a layer of purified fat and replaced every 21 hours to obtain an exquisite perfume (Jasmine, Violet, Tuberose, Rose...).

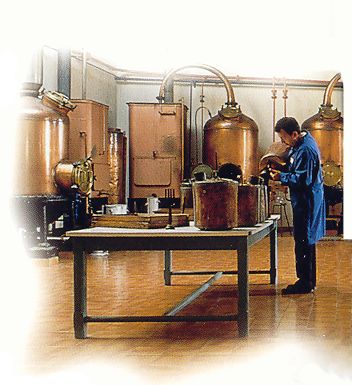

Distillation

A process which goes back to the Byzantine civilization. The odoriferous substances in the raw materials used are obtained by steam distillation. Alter distillation, the essential oils are poured into florentine flasks. Five to six tons of roses are needed to obtain one kilo of essential oil. (Rose, Neroli, Lavender, Patchouli, Petit grain, Cinnamon...).

Extraction

Through volatile solvents, this method was discovered at the end of the 19th century and is still employed these days. It consists in vacuum maceration of flowers and aromatics in solvents, which after evaporation yield a solid substance called a concreto. Once the insoluble plant waxes are removed, this provides a concentrated oil called an absolute which is the indispensable basic for any blend of quality. (Cistus, Mimosa, Jasmine, Oakmoss, Rose...). a part from these techniques there are various other operations such as rectification, fractional distillation, terpenes removal, decolourisation, etc., which improve and refine the numerous raw materials used for the blending and making of perfumes.

Copper alembics, known as "Moor's Heads", are used for distillation to obtain essential oils, but also to produce "floral waters", including Rose Water which is excellent for the skin and Orange Blossom water for its soothing.

| Spas | Care & Make-up | Health | For Men | Glossaries | Various | |||||

| Intro | Face (care) Make-up Body Hair Endless Youth Mother & Baby Corner Suncare Essentials And more... New products Spot A HairdresserMake-up Artist Directory | Healthy Diet Watching your figure Relaxation | Intro New products | All about... | Phytotherapy All Natural Fashion Perfume Jewelry & accessories And more... What is your style? |

-

Spas

Spas

-

Care & Make-up

Care & Make-up

-

Health

Health

-

For Men

For Men

-

Glossaries

Glossaries

-

Various

Various